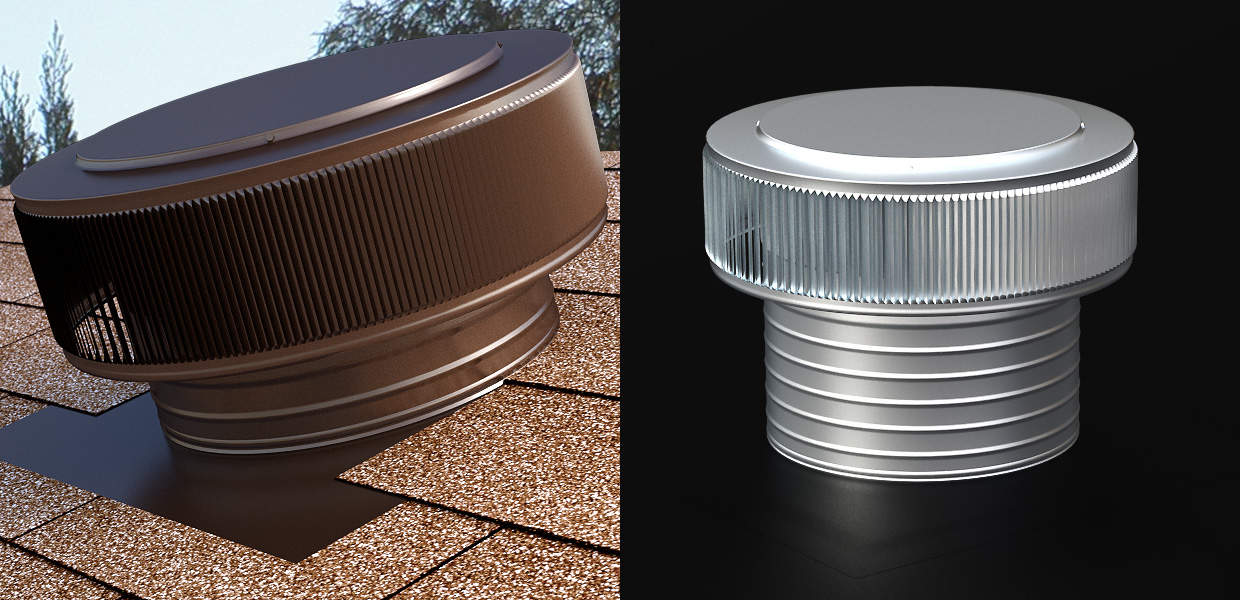

Proper roof ventilation is essential for maintaining a healthy attic environment. One effective solution is the Aura Gravity Ventilator. Unlike traditional roof turbines, this innovative vent operates without moving parts.

The Aura Gravity Ventilator utilizes a unique design that harnesses the power of the Venturi Effect and the Stack Effect to create efficient airflow. Rather than relying on spinning mechanisms, the roof vent's outer louvers create a vortex when the wind blows against them, drawing air up and out of the vent. This natural ventilation process allows for the removal of heat in the summer and moisture in the winter, ensuring year-round ventilation.

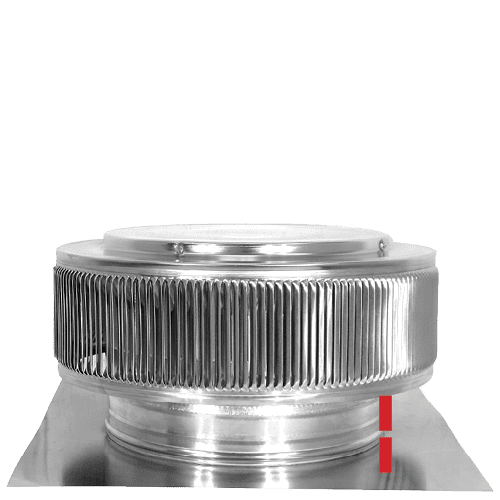

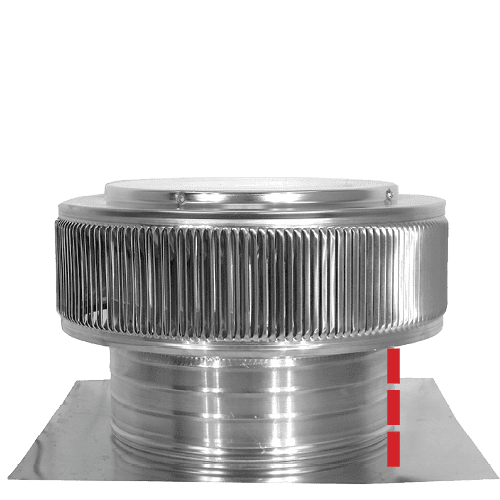

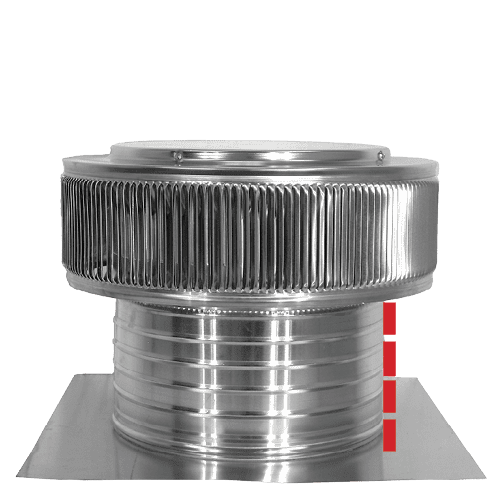

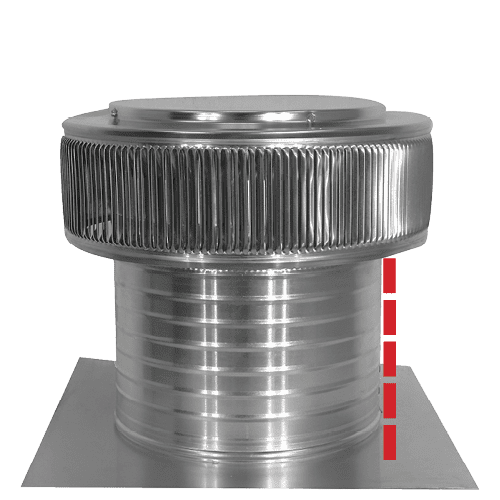

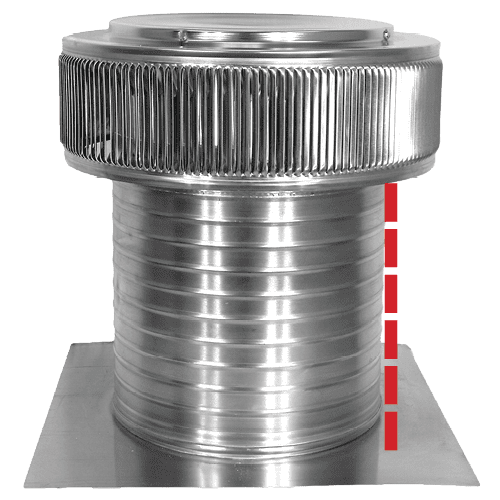

The Collar Height is the height of the neck of the vent.

Diameter | NFANet Free Area | IBC 1/300 |  2" Tall Collar |  4" Tall Collar |  6" Tall Collar |  8" Tall Collar |  12" Tall Collar |

|---|---|---|---|---|---|---|---|

| 4" | 12 | 50 | AV-4-C2 | AV-4-C4 | AV-4-C6 | AV-4-C8 | AV-4-C12 |

| 6" | 28 | 116 | AV-6-C2 | AV-6-C4 | AV-6-C6 | AV-6-C8 | AV-6-C12 |

| 8" | 50 | 208 | AV-8-C2 | AV-8-C4 | AV-8-C6 | AV-8-C8 | AV-8-C12 |

| 10" | 78 | 325 | AV-10-C2 | AV-10-C4 | AV-10-C6 | AV-10-C8 | AV-10-C12 |

| 12" | 113 | 470 | AV-12-C2 | AV-12-C4 | AV-12-C6 | AV-12-C8 | AV-12-C12 |

| 14" | 144 | 600 | AV-14-C2 | AV-14-C4 | AV-14-C6 | AV-14-C8 | AV-14-C12 |

| 16" | 200 | 833 | AV-16-C2 | AV-16-C4 | AV-16-C6 | AV-16-C8 | AV-16-C12 |

| 18" | 254 | 1058 | AV-18-C2 | AV-18-C4 | AV-18-C6 | AV-18-C8 | AV-18-C12 |

| 20" | 314 | 1308 | AV-20-C2 | AV-20-C4 | AV-20-C6 | AV-20-C8 | AV-20-C12 |

| 24" | 452 | 1883 | AV-24-C2 | AV-24-C4 | AV-24-C6 | AV-24-C8 | AV-24-C12 |

| 30" | 706 | 2941 | AV-30-C2 | AV-30-C4 | AV-30-C6 | AV-30-C8 | AV-30-C12 |

| 36" | 1017 | 4237 | AV-36-C4 | AV-36-C6 | AV-36-C8 | AV-36-C12 | |

| 42" | 1384 | 5766 | AV-42-C4 | AV-42-C6 | AV-42-C8 | AV-42-C12 | |

| 48" | 1808 | 7533 | AV-48-C4 | AV-48-C6 | AV-48-C8 | AV-48-C12 |

The Aura Gravity Ventilator louvers are formed with a triple-louver design, creating 1/8-inch openings around the roof vent. This design allows optimal airflow, preventing rain, snow, insects, and wildlife from entering the attic. The gravity vent is made of durable aluminum, ensuring it will not rust over time. It suits residential and commercial buildings and flat or steep slope roofs.

With an array of diameters and collar heights available, a homeowner or a professional can install the Aura Gravity Ventilator in any climate zone and on all types of roofs. Consult the Climate Zone Chart to determine the appropriate collar height for installation in your area. If you need to ventilate a duct, AVP offers roof vents with a tailpipe adapter. AVP provides gravity vents with curb mount flanges for installations on roof curbs.

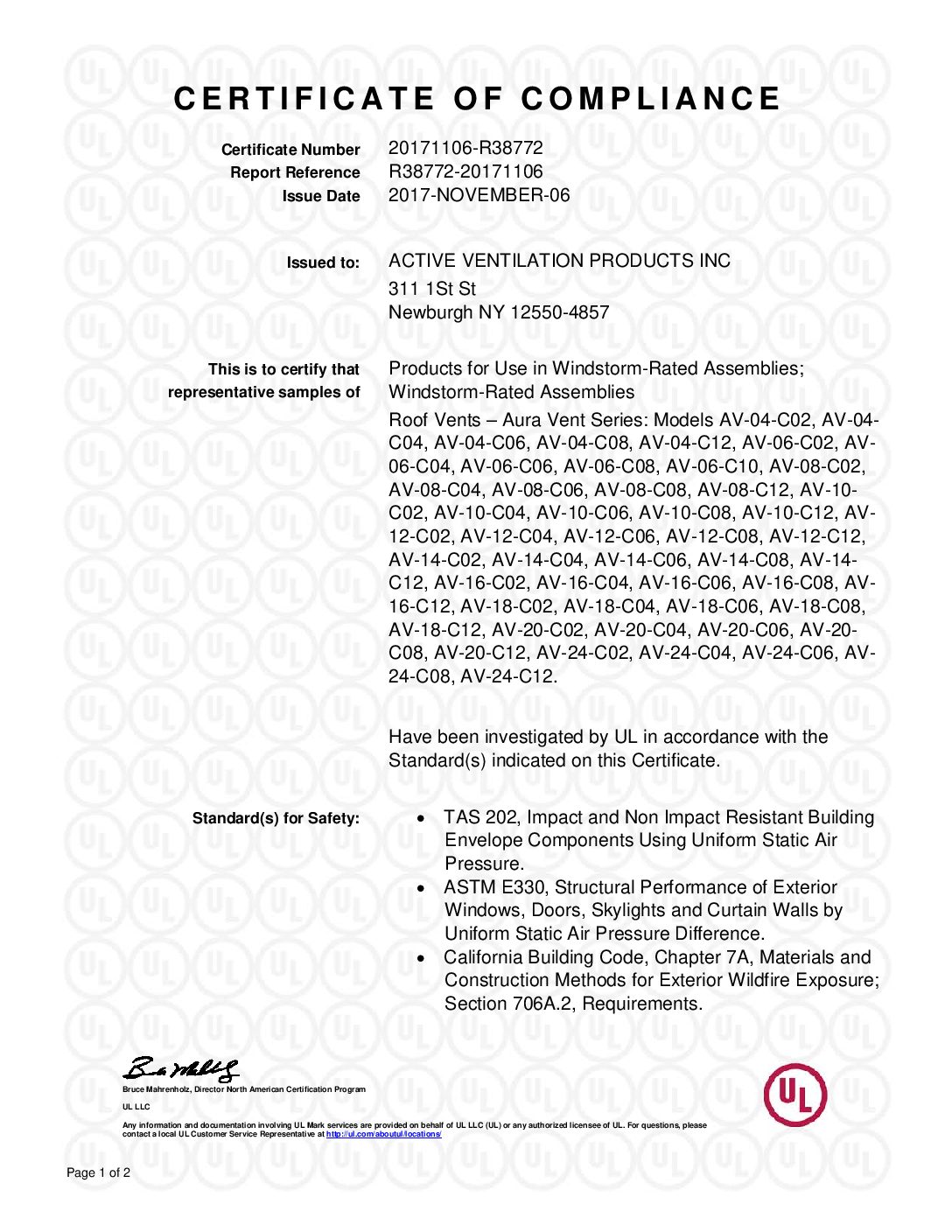

The Aura Gravity Ventilator is built to withstand extreme weather conditions. It is UL-listed and rated up to 50+ PSF, equating to over 200mph of wind pressure, surpassing the requirements for a category five hurricane. It is also certified by the Texas Department of Insurance, approved by Florida State, and conforms to the standards of CALFIRE according to third-party testing. These certifications ensure the vent will perform reliably and effectively in even the harshest climates.

Now that we understand the Aura Gravity Ventilator's features and benefits, let's delve into how this innovative vent accomplishes the function of exhaust ventilation. When an outside breeze enters the outer row of louvers, the angled design causes the wind to turn around the circumference of the vent quickly. This spinning air creates suction towards the center of the vent, resulting in a vacuum that extracts heat and moisture from the attic. The animation above demonstrates this process, and airflow ratings documented by Georgia Tech further validate the efficiency of the Aura Gravity Ventilator.

Installing the Aura Gravity Ventilator is a straightforward process. Homeowners and professionals can install these vents on both new roofs and as a replacement for old roof turbines. Consult the installation instructions provided by AVP to ensure proper installation and maximize the vent's effectiveness. The roof vents are maintenance-free.

If you have questions about the Aura Gravity Ventilator, AVP provides a comprehensive FAQ page where you can find answers to common inquiries. However, if your question still needs to be addressed, contact the sales team at [email protected] or call 845-565-7770 for personalized assistance.

In conclusion, a well-ventilated attic is crucial for maintaining the integrity of your roof and preventing issues related to excess heat and moisture. The Aura Gravity Ventilator offers a reliable and efficient solution for roof ventilation, utilizing the power of the Venturi Effect and the Stack Effect. Its durable construction, versatile design, and exceptional performance make it an excellent choice for residential and commercial buildings. Invest in the Aura Gravity Ventilator to ensure a healthy and well-ventilated attic.

Additional Information:

If you still have unanswered questions or require further assistance, our sales team is here to help. You can reach us via email at [email protected] or by calling 845-565-7770. Our dedicated team is ready to provide the guidance and support you need to make an informed decision about the Round Back Static Vent with Curb Mount Flange.

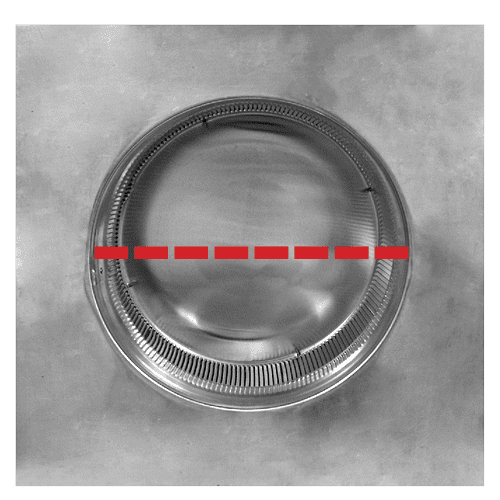

The diameter size of all roof vents determines the Net Free Area, also known as the "NFA". NFA is the measured amount of opening each vent offers at each specific size. to be available for venting air through a specific vent size. The calculator below will find the overall number of vents needed to effectively ventilate the targeted attic space.

Once you have the area, pulldown to select the specific vent diameter to show the number of vents of that size which would ventilate the specified area with both 1/300 and 1/150 rule.

*Please note

The roof vent calculation values shown above are for the exhaust portion of the roof. The same amount of net free air inches is needed for air intake as well. Proper roof ventilation consists of 50% air exhaust and 50% air intake.

Our Aura Vents have UL Certification. Check out other details and specifics on UL Product IQ™(Note: UL now requires you to have a free account to access this page)

Our Aura Vents have UL Certification. Check out other details and specifics on UL Product IQ™(Note: UL now requires you to have a free account to access this page)